Swami Vivekananda set the tone at the world religion congress stage, which has been a masterpiece of practical demonstration of Emotional Intelligence (EI)

Practical Guide For Managing Major Overhauling of Power Plants

Preface

The primary purpose of the periodic Major/ Medium overhauls in any power station is to ensure continuous generation of electricity reliably by reducing the ‘Mean Time between Failure (MTBF)” of all major equipment significantly.

Major shutdowns in any power company/ production company contributes for a significant part to total planned outage.

This procedure is a practical step by step approach for managing a major overhaul/ turnaround of power generating stations, successfully and preventing financial loss due to delay.

Objective

The objective of this procedure is to provide a clear, consistent & proven procedure of “Shutdown Management”, which will ensure completion of the Major/ Minor shutdown within the stipulated time.

Shutdown preparation considerations

- Creating a safe working environment in which no accidents happen. This is a primary consideration

- Involvement of all important internal stakeholders like workers performing maintenance, operators, contractors, the Health and safety Department and the employer.

- Prepare a overhauling & long shutdown plan.

- Review the overhaul plan as closely as possible before publishing.

- The number of tasks/ jobs to be completed will be entered from the “’Defect list”” or “” Pending job list””

- The time period of overhauling/ long shut down to be set realistically and must be adhered to, so that no generation loss is suffered.

Scope of the Major overhauling / long shutdown

The power plant planning for a major overhaul/ long shutdown requires world class planning, well-established communication structures and a well-established Environment, safety and health policy.

Planning for the overhauling involves a lot of inter related activities & most important phase because “”IF YOU FAIL TO PLAN ,YOU ARE PLANNING TO FAIL”” !!

A good Shutdown planning has the following advantages over unplanned shutdown:

| Quality shutdown management | Poor shutdown management |

| All works planned in advance. | Some is planned, most is not. |

| Planned & scheduled jobs get priority. | Planned & scheduled jobs gets overridden by other jobs. |

| Materials & spares availability are planned. | Materials & spares availability are haphazard. |

| OEM/Contractors tie up are planned. | OEM/Contractors support is doubtful. |

| Planning & scheduling are well documented with clear accountability. | Planning & scheduling are half cooked without any well-defined accountability. |

| Shutdown completion on time, thereby reducing business loss. | Shutdown completion most of the time is extended, thereby incurring business loss. |

| Add-on works are rare. | Add-on works are common. |

ESSENCE OF PLANNING & SCHEDULING

Why do we plan?

To increase productivity --- Right answer

To provide job packages --- Wrong answer

- Planning supports improving individual jobs repeated over time – A cycle of improvement of each job.

- Planning supports advance scheduling by identifying skills of experts.

- Scheduling sets goal to assign a sufficient amount of work.

RESOURCES

In order to complete Total Plant shutdown within stipulated time following resources will be required:

- Mobilization of huge manpower (Experts, Skilled, semi-skilled & un-skilled).

- Arrangement of necessary spares and consumables.

- Deployment of various contractors/service providers & Logistics.

- Ordering of spares and OEM experts on time.

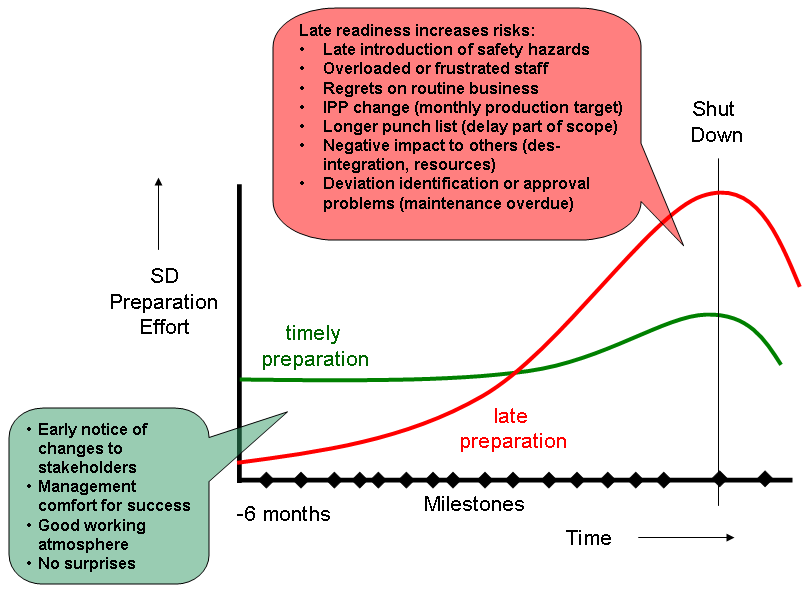

Organizations have to start the planning activities at least 4 to 5 months in advance, in order to fulfil above requirement

An effective system of shutdown management planning should meet the following criteria

- Manage & prioritize all the job plans.

- Able to achieve the schedules.

- Manage plant/site access for resources, vehicle, equipment & tools.

- Manage indirect hire, contractor, and sub-contractor & service personnel at site/plant.

TEAM BUILDING

Accordingly, a team for managing major Overhauling/ turnaround to be in place well in advance and the following activities to be carried out:

- Planning.

- Scheduling of the jobs.

- Verification of the shut- down job list.

- Identifying the resources required for every job.

- Target date to start hiring OEM/ Experts & other services.

- Target date to start placing P.O for spares/ consumables.

- Identifying the accountable person.

- Follow up of target dates.

- Liaison with Head office/Corporate office for support services.

- Making arrangement for lodging & fooding for service providers at site.

- Pre-shutdown data collection.

- Preparation for timely handing over of PTWs (Permit To Work) and Lockout & Tagout (LOTO) of equipment.

- Post shutdown return of PTW & normalization of LOTO.

- Post shutdown normalization, testing, checking.

- Start- up of the machine.

The core team should be ideally consisting of and led by position as O&M Head:

- HODs from Operation, Mechanical, Electrical, Instrumentation, Technical services, Maintenance planning, Safety departments to be included.

- HoDs from Purchase, Stores, Finance, HR, Contracts department will also be included periodically for closer co-ordination in their respective areas.

PROCEDURE

- Identification of personnel and departments and assignment of responsibility:

- Overall shutdown co-ordinator – Head (O&M)

- Planning & Scheduling co-ordinator – Technical services head / Planning deptt head.

- Job planning & scheduling input – OEM/LTSA contractor(if applicable)/O&M contractor(If applicable) / maintenance heads of organization.

- Material/ spares follow-up – Respective maintenance heads

- Services(For technical aspects) follow-up – Organization contracts/ purchase deptt/ Maintenance heads/ Head office procurement (Where ever applicable)

- Logistics follow-up – Site/ Head office Logistics depts.

- Tools, Tackles, instruments calibration/inspection – Respective maintenance departments & safety department to check the calibration/ statutory testing validity, as applicable.

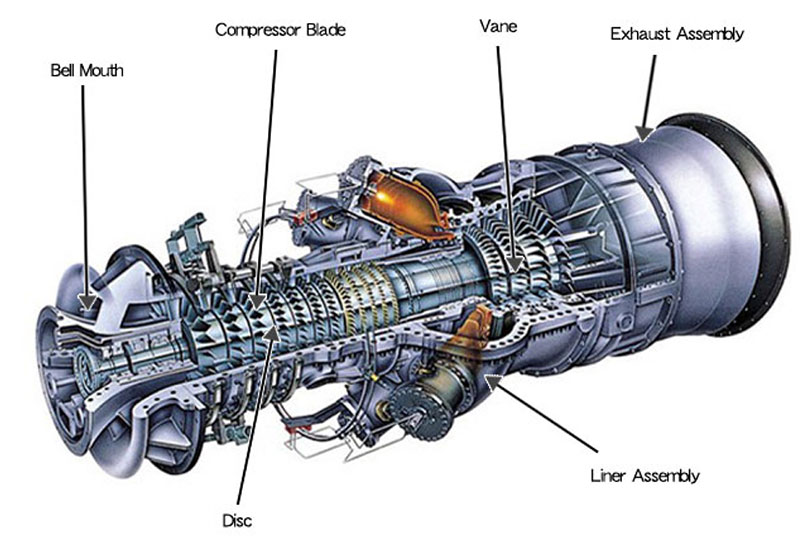

- Identify Lay-down area for Gas turbine and other spares – To be done by Maintenance deptt heads along with OEM/ Engg/Tech Service provider company at least two months in advance.

- Regular shutdown planning meetings to be started and meeting schedule to be finalized at least three months in advance.

- Preparation of Job safety analysis by operation & safety departments, at least one month in advance.

- One of the most critical activity is the coordination of overhead crane management, as overhead crane and multiple activities requiring crane to be co-ordinated. This must be done in a very meticulous way so that no work should suffer.

- Another critical area is outsourcing of skilled & semi-skilled manpower. Organizations can keep provision to hire 30% extra manpower & this can provide good support during shutdown. (Where manpower in the organization is limited).

- Setting up a full-fledged medical support system at site & tie up with Government hospital nearby.

- Advance training imparted by safety department on various PTWs like work at height, hot work, Excavation, Line break work etc.

- Imparting safety training to external service personnel on arrival at site.

PLANNING & SCHEDULING

- Level-1 Scheduling (L-1)

- Level-2 Scheduling (L-2)

- Level-3 Scheduling (L-3)

- Level-4 Scheduling (L-4)

L1-Schedule comprises key events or major milestones selected as a result of coordination between client and contractor. It does represent in the format of list, summary schedule or in the form of Bar chart.

L2-Schedule comprises of Critical network activities and other project management selected activities with mainly ES (Early start) and EF (Early Finish) dates. L2 schedule provides integral plan of the Project activities for Project management.

L3-Schedule shows lowest level of details necessary to complete the project through Job Completion and also to finalize remaining requirements for the total project. For e.g., if L1 shows structural steel engineering activity/task then in L3 of this particular activity likely to break up in more activities with shorter durations such as define and collect loads, drawing specifications etc.

L4- Schedule shows two to six week look ahead schedule that shows resources assigned, detailed and work activities and L4 schedule is mainly used planning and progress reporting purposes and advance planning for near term future week work.

Phases of major shutdown management

- Initiation

- Form “Shutdown Management group” with Head (O&M) as head.

- Kick-off meeting with all departments and stake holders.

- Setting a time frame to achieve Freezing of Final L-4 schedule.

- Planning & Preparation

- Justification of the jobs being done in shutdown: Appears in preliminary job list.

- Job list review with all possible spares and manpower availability.

- Develop Schedule, Critical Path, create baseline & track progress against baseline: In this level we had broken down the activities up to L-4 schedule for very good clarity.

- Risk Analysis-Use Risk Management Process: Here we used tools like HIRA/PHA/HAZOP etc

- Execution

- Meetings: Circulate the morning / afternoon meeting timing and ensure that the meeting conducted on time and completed the meeting within 45 minutes to one hours max so that all personnel can go back to work early.

- Tracking progress against Schedule: Rigorous tracking is the key of the early completion.

- Show if work is falling behind schedule: Analysing each job and raise alarm to maintenance team in the event any activity slows down.

- Prepare a catch-up schedule: This is also very important so as to make up the schedule.

- Close out

- Post shutdown Preliminary report preparation within 15 days: Synopsis

- Detailed report publishing: within 30 days

- SWOT (Strength, Weakness, Opportunity, Threat) analysis: Consolidate issues, Feedback to Management

- Lesson Learnt i.e. Feedback for improvement – within 30 days (Can be done internally by the organization in conjunction with the OEM/ Servicing companies)

Conclusion

In order to achieve the successful Shutdown management programme, Planning is the ESSENCE. If planning is covering 80% of the activity, it is sure that all other activities will be on schedule.

successful completion of total plant shutdown ahead of time or ON time is money. Hence set the experience as a baseline for all Major Maintenance in future so that a system driven culture can be wholly incorporated for maintenance activities.

READ THeSe NEXT

Energy and Water audit must go hand in hand in large commercial complexes.

Here is a short guide for achieving the same.

ENERGY EFFICIENCY A POWERFUL TOOL FOR dE-CARBONIZATION

Congratulation

You are a wonderful teacher, boss, leader, and friend. You are everything one could look for in a good mentor. You groomed me to be sound professionals and made working with you an interesting and memorable experience. I will always be grateful to you for your support and kindness

It is good initiative taken by you to develop the power plant engineers on planing, shut down & O&M , environment management as well as conservation of natural resources.

The Technical Aspects Presented Beautifully, with a hint of simplicity in understanding as far as the intention to reach maximum amount to technically enriched minds are concerned .

Approch to the Matter is Highly Appreciated with a personified flair of compactness yet keeping it to the core of Technical Persona.

Appreciation , well Deserved.