You are actually paying heavily for your procratination, though you are unaware of the same. Procratination costa you heavily. Hence folllow the 9-proven steps to combat procratination.

Double Energy Efficiency With VARS

Vapour Absorption Refrigeration System (VARS)

In recent years, global warming is the major challenge in front of the whole world.

It is well known fact that there are SEVEN greenhouse gases (GHG) which are responsible for the global warming.

Apart from the above, Ozone depletion is also a major concern.

Out of seven gases, one is HFC (Hydrofluorocarbon).

In vapour compression refrigeration system (VCR) chlorinated fluorocarbons (CFCs, also called Freons): R-11, R-12, R-21, R-22 and R-502 gases are used.

Hydrofluorocarbons (HFCs) are often substituted for R-22 because of their lower ozone depletion potential, but these refrigerants often have a higher GWP (Global Warming Potential).

However, in Vapour absorption refrigeration system (VARS), Absorption chillers do not use CFCs or HCFCs, refrigerants that contribute to ozone depletion and global warming.

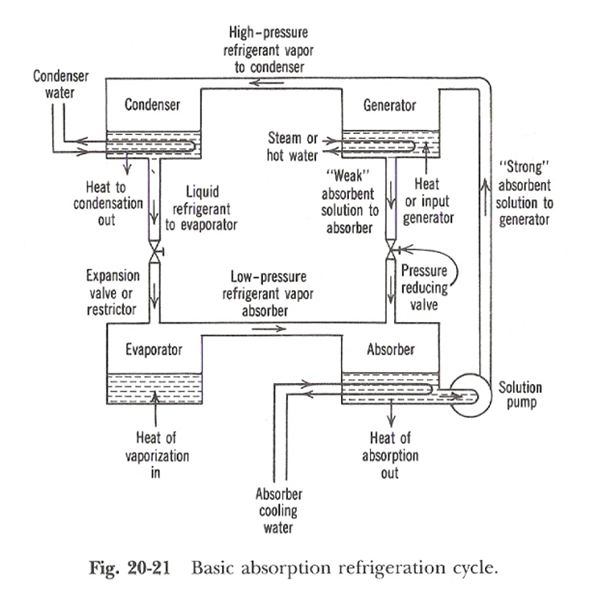

In VARS, the compressor is replaced by an absorber, pump, and generator. The key components of a VARS system are as follows:

- Absorber: This component absorbs the low-pressure refrigerant vapors into a solution of the refrigerant and absorbent.

- Pump: The pump sucks the strong solution from the absorber and delivers it to the generator at a higher pressure.

- Generator: The generator heats the strong solution using heating coils, solar energy, or waste heat. As the refrigerant has a lower boiling point than the absorbent, the refrigerant vaporizes, leaving the solution weaker.

Other equipment are:

- Pressure Relief Valve

- Condenser

- Expansion Device

- Evaporator

Source: HVAC School

Types of VARS:

(1) Single-Effect Absorption Chillers:

These systems have a single generator and are the simplest form of VARS.

They operate at relatively low temperatures and have a limited coefficient of performance (COP).

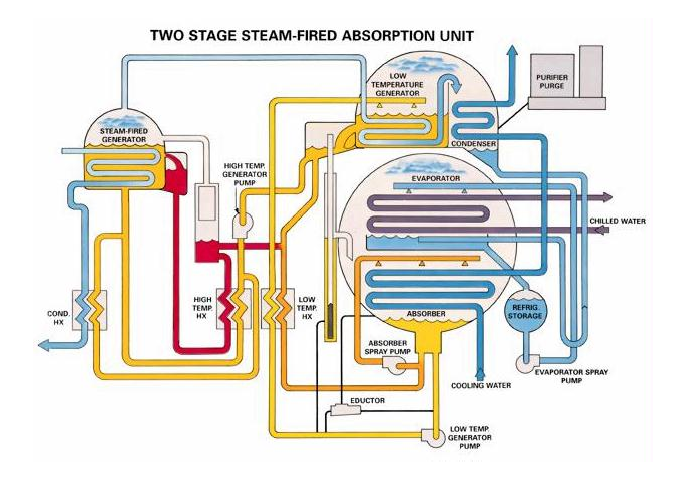

(2) Double-Effect Absorption Chillers:

These systems use two generators in series.

The first generator produces a weak solution, which then enters the second generator for further concentration.

Double-effect chillers offer improved COP compared to single-effect chillers.

(3) Triple-Effect Absorption Chillers:

These advanced systems have three generators in series.

They achieve even higher COPs by utilizing multiple stages of concentration.

Types of Energy Sources:

The energy required for the vapor absorption refrigeration cycle can use various sources:

(A) Direct Heat Sources:

These include natural gas, steam, or hot water, which directly provide the heat needed for the generation process.

(B) Waste Heat Recovery:

Absorption refrigeration systems can utilize waste heat from industrial processes or renewable energy sources, making them more energy-efficient and environmentally friendly.

(C) Solar Energy: Solar-powered absorption refrigeration systems use solar collectors to capture and convert solar energy into heat, which is then used in the generation process.

Energy Transfer in a VAR system:

The energy transfer within a Vapour Absorption Refrigeration System involves following steps:

- Heat Supplied to the Generator:

This heat input occurs in the generator, where the strong solution is heated. The generator can be powered by waste heat from boilers, turbine exhaust steam, or even solar energy.

- Heat Gained at the Evaporator:

The evaporator absorbs heat from the surroundings, causing the refrigerant to evaporate and cool the system. (This is actually space cooling).

- Heat Rejected from the Absorber:

The absorber releases heat as the refrigerant vapors are absorbed into the solution.

The pump work is necessary to move the strong solution from the absorber to the generator.

Energy transfer equations in a vapor absorption refrigeration system:

Energy transfer in a vapor absorption refrigeration system is the most important process that enables the system to produce cooling effects by transferring heat from one place to another. Following are the heat transfer processes in a VARS:

(1) Heat Absorption in the Evaporator (Q_evap):

𝑄evap=𝑚⋅ℎfg

Where:

Qevap = Heat absorbed in the evaporator (in Joules or BTU)

𝑚m = Mass flow rate of refrigerant (in kg/s or lb/s)

ℎfg = Latent heat of vaporization (in Joules/kg or BTU/lb)

(2) Heat Release in the Absorber (Q_abs):

𝑄abs=𝑚⋅(ℎ1−ℎ4)

Where:

𝑄abs = Heat released in the absorber (in Joules or BTU)

𝑚m = Mass flow rate of refrigerant (in kg/s or lb/s)

ℎ1 = Enthalpy of the refrigerant leaving the evaporator (in Joules/kg or BTU/lb)

ℎ4 = Enthalpy of the refrigerant entering the absorber (in Joules/kg or BTU/lb)

(3) Heat Input in the Generator (Q_gen):

𝑄gen=𝑚𝑠⋅(ℎ3−ℎ2)

Where:

𝑄gen = Heat input in the generator (in Joules or BTU)

𝑚𝑠 = Mass flow rate of absorbent solution (in kg/s or lb/s)

ℎ2 = Enthalpy of the absorbent solution entering the generator (in Joules/kg or BTU/lb)

ℎ3 = Enthalpy of the absorbent solution leaving the generator (in Joules/kg or BTU/lb)

(4) Heat Rejection in the Condenser (Q_cond):

𝑄cond=𝑚⋅(ℎ2−ℎ1)

Where:

𝑄cond = Heat rejected in the condenser (in Joules or BTU)

𝑚 = Mass flow rate of refrigerant (in kg/s or lb/s)

ℎ1 = Enthalpy of the refrigerant leaving the evaporator (in Joules/kg or BTU/lb)

ℎ2 = Enthalpy of the refrigerant entering the condenser (in Joules/kg or BTU/lb)

Above equations describe the energy transfer processes involved in a vapor absorption refrigeration system. These are essential for analysing and designing efficient absorption refrigeration systems.

Advantages of VARS:

- Utilizes waste heat for operation.

- No mechanical compressor, reducing maintenance costs.

- Suitable for large-scale refrigeration loads.

Applications:

- VAM chiller (Example- Gas Turbine inlet air chiding system)

- Suitable for larger air conditioning or water chilling.

- Useful in places having electricity problems for refrigeration and air conditioning.

- Large-capacity refrigeration in bigger plants.

- Electrolux refrigerator (In some cases).

Understanding this process is essential for grasping how absorption refrigeration systems work and how they differ from vapor compression systems. Let's delve into the intricacies of energy transfer within a vapor absorption refrigeration system.

Efficiency and Applications:

Vapor absorption refrigeration systems are known for their high efficiency and suitability for applications where waste heat or low-grade heat sources are available. They are commonly used in following areas:

(I) Industrial processes.

(II) Commercial buildings.

(III) Off-grid or remote locations where electricity is scarce or expensive.

Conclusion:

Energy transfer in vapor absorption refrigeration systems plays an important role right from designing to performance calculations.

VARS presently gaining ground for energy efficiency and low-quality energy usage in the system.

Towards more sustainable HVAC systems, VARS can contribute a lot.

Source : EnggCyclopedia

READ THeSe NEXT

Persons are always driven by finding happioness. But reality is neither happinees nor negetive situations, stay longer. People recover from both the situations in course of time. This is called HEDONIC ADAPTATION.

Here is a blog on Hedonic Adaptation.

Water crisis for India is loomimng large by 2025 to 20230. Not o0nly India this is going to affact whole world;s population. All nations must therefore take massive drive to sensitize all sections of people.

If not controlled, water security will be in danger.