You are actually paying heavily for your procratination, though you are unaware of the same. Procratination costa you heavily. Hence folllow the 9-proven steps to combat procratination.

Boiler water Phosphate Treatment – very important to save generation losses

Introduction

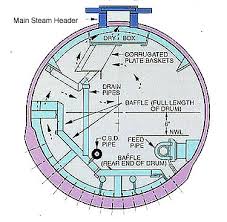

Phosphate treatment is adopted in the boiler drum to avoid the scale on the metal surfaces, in power plant boilers, which are operating with medium to high pressure & temperature.

It is well known that when the pressure and temperature of boiler drum increases, solubility of dissolved minerals decrease. This phenomenon is the prime reason for scaling on the boiler tube & boiler drum surfaces.

Scales on the boiler drum & water tube surfaces adversely affects the heat transfer causing failure of tubes and boiler drum.

Impact of scaling on the steam generating surfaces

- Overheating of the tubes & Boiler drum, thereby causing failure/cracking etc.

- Restriction of steam & water circulation,

- Unscheduled shut down & generation/production loss

- Injury to working persons due to accident,

- Increases the overall generation cost.

Apart from the above, If the steam gets contaminated with minerals then this can lead to deposition on steam turbine blades. As the deposition of minerals take place on steam turbine blades there is a danger for sluggishness of the turbine operation, imbalance of rotor, damage of the blades.

In order to avoid all aforementioned problems phosphate treatment is adopted for the boiler drum.

Various types of phosphate treatment methods for boiler drum are available. The adaptation of phosphate treatment always depends upon the design, application & boiler drum pressure.

Types of phosphate Treatment

- Phosphate treatment: - This is applicable for low pressure boiler drums. Boiler drum pressure ranges from 5 bar to 30 bar.

In this phosphate treatment procedure, residual phosphate is maintained between 8 to 10 ppm & pH of boiler water is maintained between 10.5 to 11.00.

- Coordinate Phosphate Treatment: - This is applicable for medium pressure boiler drum. Boiler drum pressure ranges 30 bar to 80 bar.

In the coordinate phosphate treatment, sodium to phosphate ratio is maintained 3.0. In this type of treatment there is a chance of “caustic gauging” problem due to free alkalinity. In order to avoid “caustic gauging” problem, it is sometimes suggested to switch over to “congruent phosphate treatment”.

- Congruent Phosphate Treatment: - This type of treatment is applicable for medium pressure boiler drum.

Boiler drum pressure ranges between 30 bar to 80 bar. In the congruent phosphate treatment, sodium to phosphate ratio is reduced further between 2.6 to 2.8.

In this treatment there is a chance of “phosphate hide out” problem. Due to phosphate hide out water chemistry becomes in corrosive in nature.

- Equilibrium Phosphate Treatment: This type of treatment is applicable for medium to high pressure boiler drum/ Sub critical pressure operation of boiler drum.

In this treatment there is no requirement to maintain sodium to phosphate ratio. However residual phosphate is maintained between 0.5 to 2.0 ppm & boiler drum water pH between 9.2 to 9.8.

By Suezwatertechnology

Advantages & disadvantages of phosphate treatment

Advantages

- Boiler water remain alkaline, hence there is no problem of corrosion.

- Additionally, di-sodium phosphate is available to maintain boiler drum pH.

- Magnetite layer inside the boiler drum will be in good condition.

- This type of treatment Keeps the silica always in soluble form.

- This type of treatment Keeps the sludge always in floating condition for easier blowdown.

Disadvantages

- Acid Phosphate corrosion can take place due to “phosphate hide out”.

- Phosphate reacts with magnetite layer to from “marcasite” as a corrosion product.

- “Sodium carry over” takes place in the steam if excess amount of tri-sodium phosphate dosed in the boiler drum.

This can lead to deposit of Sodium on steam turbine blades.

By researchgate.net

Conclusion

Phosphate treatment adoption for boiler drum water always depends on the design, application & drum pressure.

Selection of phosphate treatment is very important in order to avoid any adverse impact on the Water-Steam system.

READ THeSe NEXT

Persons are always driven by finding happioness. But reality is neither happinees nor negetive situations, stay longer. People recover from both the situations in course of time. This is called HEDONIC ADAPTATION.

Here is a blog on Hedonic Adaptation.

Water crisis for India is loomimng large by 2025 to 20230. Not o0nly India this is going to affact whole world;s population. All nations must therefore take massive drive to sensitize all sections of people.

If not controlled, water security will be in danger.

This article is a very goood one with an eye to optimize the Boiler water phosphate treatment.